No. You don’t need a giant set of cups in all different sizes. You could actually use just one cup for everything.

Seriously.

Key Takeaways

If you haven’t figured it out by now, we prefer a no BS approach to welding. We like to keep it as simple as possible. You really don’t need a bunch of different cups for every TIG job you encounter. In fact, you probably don’t even need half of the cups you think you do.

The purpose of a TIG cup is to direct shielding gas to the part you are welding. Literally - that’s all they do. So why are there so many different sizes? Procedures.

But if you’re not following a written procedure - you can follow a very simple set of rules for every cup! We will get into which cup is used for different metals in a moment, but first, let’s uncover those rules.

Each cup is referenced by a number

The number is the diameter of the outlet measured in 1/16 inch increments

That measurement also corresponds to tungsten stick-out length

It’s a good idea to follow the tungsten stick-out rule closely. Not only does this ensure the shielding provided by the cup is adequate, but it also means you are not cutting off gas flow to your part. It also means you aren’t operating it with too much which can cause more coverage issues, blowouts and more.

The stick-out rule is a “window”

You can stick out a little more or a little less as long as the gas flow is set correctly.

The number of the cup also tells you where to set the gas flow at. If you gas flow is not set properly, you are going to encounter problems… lots of problems. Too little gas flow can cause the weld to overheat and show unsightly oxidation. Too much gas flow is actually really bad as it can stir the atmosphere into the shielding zone which is just like having no gas at all. It’s also extremely wasteful.

Gas Flow Formula (CFH)

Cup Number X 2 = Minimum Gas flow in CFH

Cup number X 2.5 = Maximum Gas Flow in CFH

Gas flow is measured at the center of the ball on a standard flow meter

Gas Flow Formula (Lpm)

Cup Number = Minimum Gas Flow in Lpm

Cup number + 2 = Maximum Gas Flow in Lpm

Gas flow is measured at the center of the ball on a standard flow meter

DO NOT SET GAS FLOW HIGHER OR LOWER THAN WHAT IS RECOMMENDED.

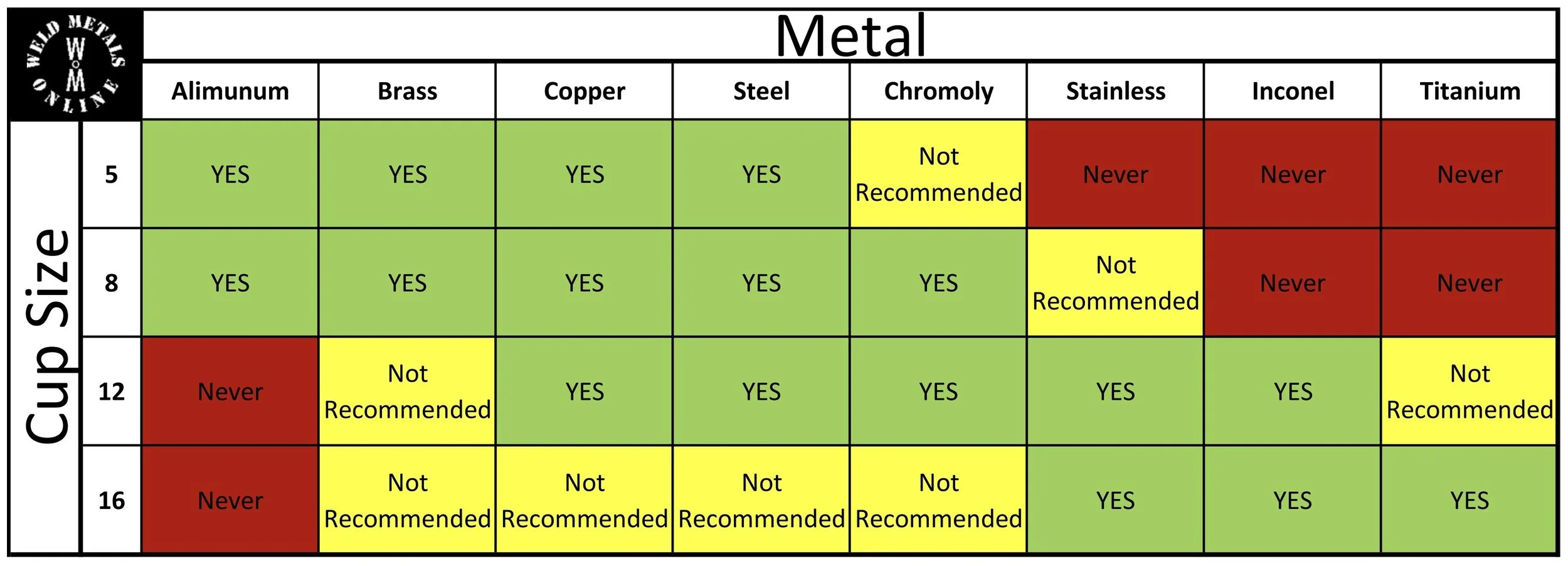

So which cup should you use and why? Believe it or not, Justin only uses 3 cups for every single metal he welds from aluminum to Titanium and more - 5, 12 and 16.

5# standard or gas lens cup for aluminum. The smaller diameter means more control and less etching on aluminum. It also uses less gas which aluminum does not need a lot of

8# gas lens cup is a great all purpose cup which can be used on aluminum, steel and even stainless if you’re good at it

12# gas lens cup is great for decorative welds and rainbow pattern making. If you can afford the argon, a 12 is a great general purpose cup. NEVER use it on aluminum

16# gas lens cup is for the exotics like titanium. It’s also great for stainless if the goal is to keep most or all of the color out of it.

Cheap consumables produce cheap results. This includes cups and bargain kits with a bunch of different sizes and types. The classic waste of money almost everyone eventually realizes is the full set of Pyrex cups on Amazon with the infamous green o-rings and crappy gas lenses that fall apart. Trust us when we say - they suck.

Quality products come from major brand names (not bargain names). If you find it on Amazon competing with something that looks just like it - guaranteed it’s cheap. But there are a few rules you can follow when it comes to buying quality consumables.

Premium Brands: CK Worldwide, Furick, Edge, etc.

OEM Brands: Miller, Lincoln, Esab, Primeweld, etc.

House Brands (welding supply store): Radnor, Prostar, etc.

“Go ahead and buy the big fancy kit. You’ll eventually discover that the only difference between a No. 8 cup and a No. 7 cup is...

One.”

This article is proudly written with 0.00% AI.