How lucky could I get twice? How many good friends do I have looking out for me and my projects? I was already extremely lucky once when it came to sourcing the RHD swap parts for the truck, but now I ran into another problem: I have no house or shop.

SEMA had come and gone and I finally saw a little break in the holiday schedule. My calendar schedule is pretty hectic when it comes to these builds. The beginning of the year is the start of race season, early summer kicks off the show season, and late summer to fall is SEMA season (where the real crunch happens). I was between houses after SEMA was over, so I had no garage space to work in, and I wasn't in a shop at the time. I had an opening in my timeline, but had nowhere to perform the swap.

*Picture Note* - I scheduled the job out for the greatest efficiency to work in the allotted time. The order this Build Blog is written is out of order to the order in which I performed the swap. Some pics may show both night and day time, but the job is still the same.

Another long time friend heard of my issue and came to the rescue with offering up his garage. There was only one little catch - I only had 4 work days to do it, and those 4 days were the 4 days before Christmas. This would be my 7th RHD conversion (first on a Mighty Max), and I am pretty good at what I do, but is that even possible?

I had one chance to make this swap happen. By this time, I had been waiting since September to convert the MiEvo to RHD, so I took it on as a personal challenge.

I arrived with half of my shop packed in the back of the truck right as the sun was starting to set on December 21st. After unloading and setting up in the garage, the work could begin.

In order to operate as efficiently as possible, I took an hour to completely strip everything out of the truck including the engine and transmission. It boils down to spend 30 minutes pulling the engine now, or spend hours working around it later. I chose the former.

Once the tear down was complete, I only had a couple hours to get cracking on this job. I was already an hour ahead of schedule thanks to my friend helping, so might as well get a jump on it. I can only work until 10:00PM, so I'm going all the way til 9:59:59.

There is a real blessing in the manufacturing methods of this particular truck. Since it was manufactured in Japan, and offered in many countries around the world, the firewall is actually mirrored. This means a firewall swap is not necessary, but there are a select few differences that must be addressed or else a failure is almost guaranteed.

I started right away with getting the dash framework mounted up. The steering column mount bracket is identical on both RHD and LHD configurations. It was simply swapped over by drilling out the spot welds and transplanting it to the right side.

Once the frame work was in place, the mounting of the clutch and brake master cylinder could begin. I am converting my transmission from a cable clutch to a hydraulic option just as an overseas installation would be. The stamping is conveniently placed in the sheet metal for it to be measured and cut out for install.

It only took a few moments to properly measure and drill the 3 holes needed for the clutch master, and 5 for the brake master cylinders.

Once the holes were in, I tossed them in for a quick mock-up mounting.

To close out the night, I tossed the dash frame with the dash itself in to get a taste of whats to come.

I did get my first taste of reality that I already considered that night. I didn't have the RHD pedal assemblies. Ordering a set would be out of the question because they would never arrive in time. All I could do was continue to work out a solution which is a little easier now that I can actually see what is needed to be done. Either way, he first night was over and I was already ahead of schedule. So far, so good.

Day two brought on all the welding and sheet metal work. The first job was to get the steering column in place. I started with a simple transplant of the steering hole. The easiest way to transplant is to cut the easiest shape out as possible, measure and trace to the other side, then cut and weld..

To save time, I opted to use the MIG welded for the sheet metal work. It does take a few extra minutes to grind down, but all in all is less time than using the TIG.

If you look carefully, you can see a hole above the right side placement where the AC hoses used to pass through the firewall. This only required a small patch cut from extra sheet metal.

The HVAC blower install requires another quick mod to function correctly. In order to access outside air, an access hole had to be cut into the left side. This is conveniently found in the stamping of the sheet metal.

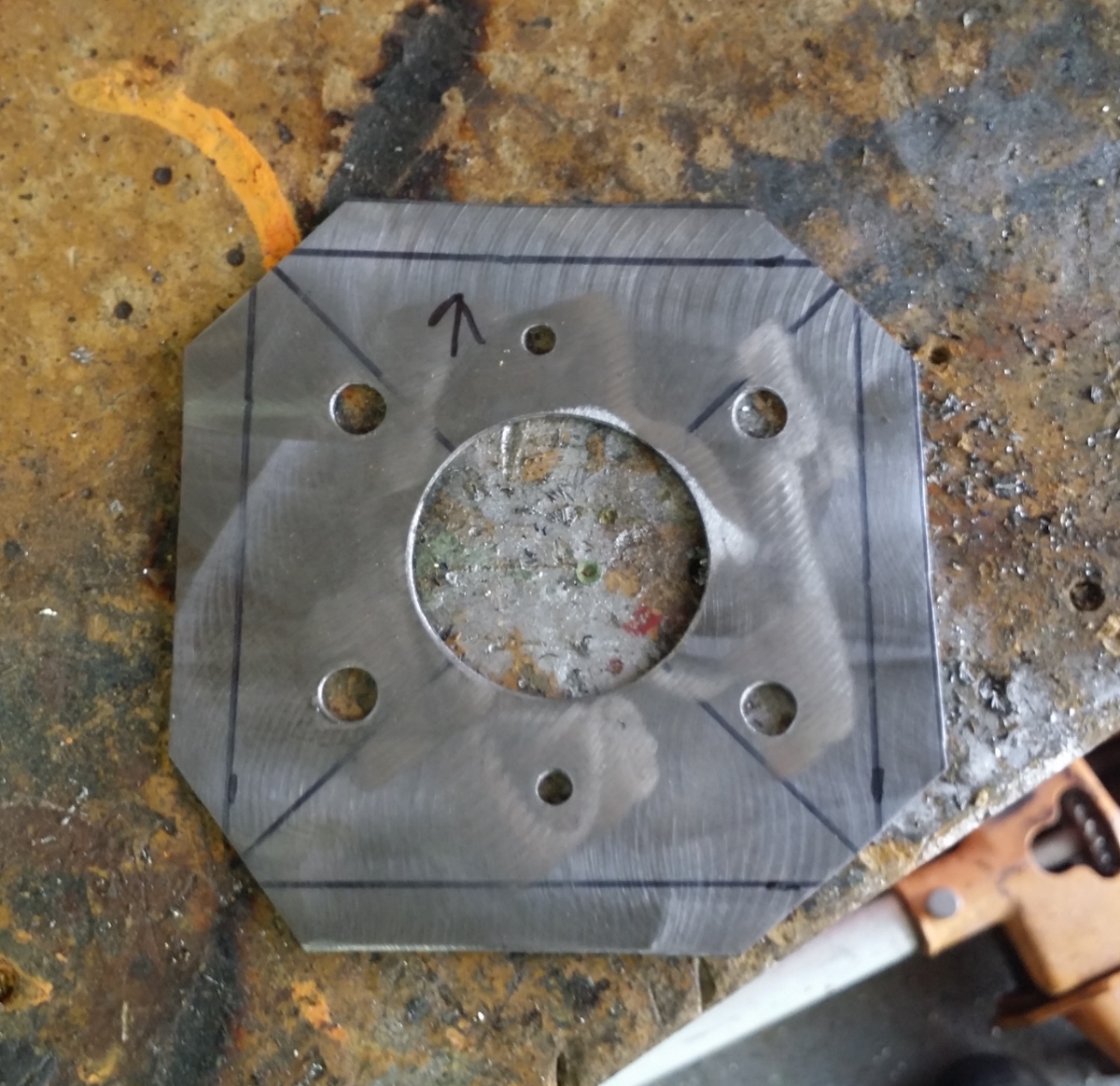

The factory firewall sheet metal is by far not the thickest stuff in the world. It actually more like the definition of paper thin. The left side of the firewall has a reinforcement section welded to the firewall around the components. The only problem with that is it can not be transplanted to the right side since it is mirrored. It simply does not match the stamping of the opposite side. Failure of the sheet metal would almost be guaranteed if you installed components to the right side without proper reinforcements to keep the sheet metal from tearing away every time you step on the brake or clutch. Rather than trying to track down a part that would likely never be found, I opted for doing what I do best: I fabricated the reinforcements.

Reinforcement plates were fabricated from 18ga sheet metal.

There isn't much of a trick to this, but it is imperative that your holes be lined up correctly. I like to add spot welds to each plate to keep the plate from rattling.

Only one plate was needed around the clutch master cylinder, while the brake master cylinder was reinforced with two plates.

After some strong welds were laid, followed by a smooth grind, I was faced with two very big holes in the firewall that needed to be patched.

As mentioned earlier, one rather big flaw with the Mighty Max and Ram D50 is the firewall sheet metal. The factory clutch action for a left hand driven 2WD is a cable. The reinforcement for the cable bulkhead is just not strong enough. As such, a common problem is the cable bulkhead will literally rip out of the firewall. My truck was no different with he previous owner. Judging by the looks of it, he did the best job he could to repair it. I simply couldn't keep it on the truck, so I had to delete it completely.

There really is no fixing it to make it less visible, nor was there a way to blend it in with the rest of the firewall. You simply cant leave it there and try to play it off as some other functional piece. If you look at the inside pic posted just above, you will see just how torn up the firewall is. This kind of presents a huge challenge to fix. All of the torn sections around the patch are on the raised/stamped section of the firewall.

It took some delicate trimming along with some extreme care when welding because the metal is very fatigued. At the end of it all, I'm proud to say that very little filler (if any) will be needed to cover this section.

The final round and finishing pieces needed to get this Mighty Max Right Hand Drive Swap back on the road! Check out what needed to be solved and a cool Q & A at the end!!