What if you had to buy two of everything and throw half of it away just to get one complete fuel system for your build. Could you do it?

That's part of the story on this system actually. Here's the thing - there isn't a "4 rotor fuel kit" that I am aware of. There was no way to purchase only two primary fuel rails from SARD, so how else do you get the components you want from one of your desired manufacturers? The answer is buy two and throw half of the system away. Now add the custom factor. Everything in between the main components has to be built, so take another handful of included hardware and fittings and toss them as well. Still think you can manage?

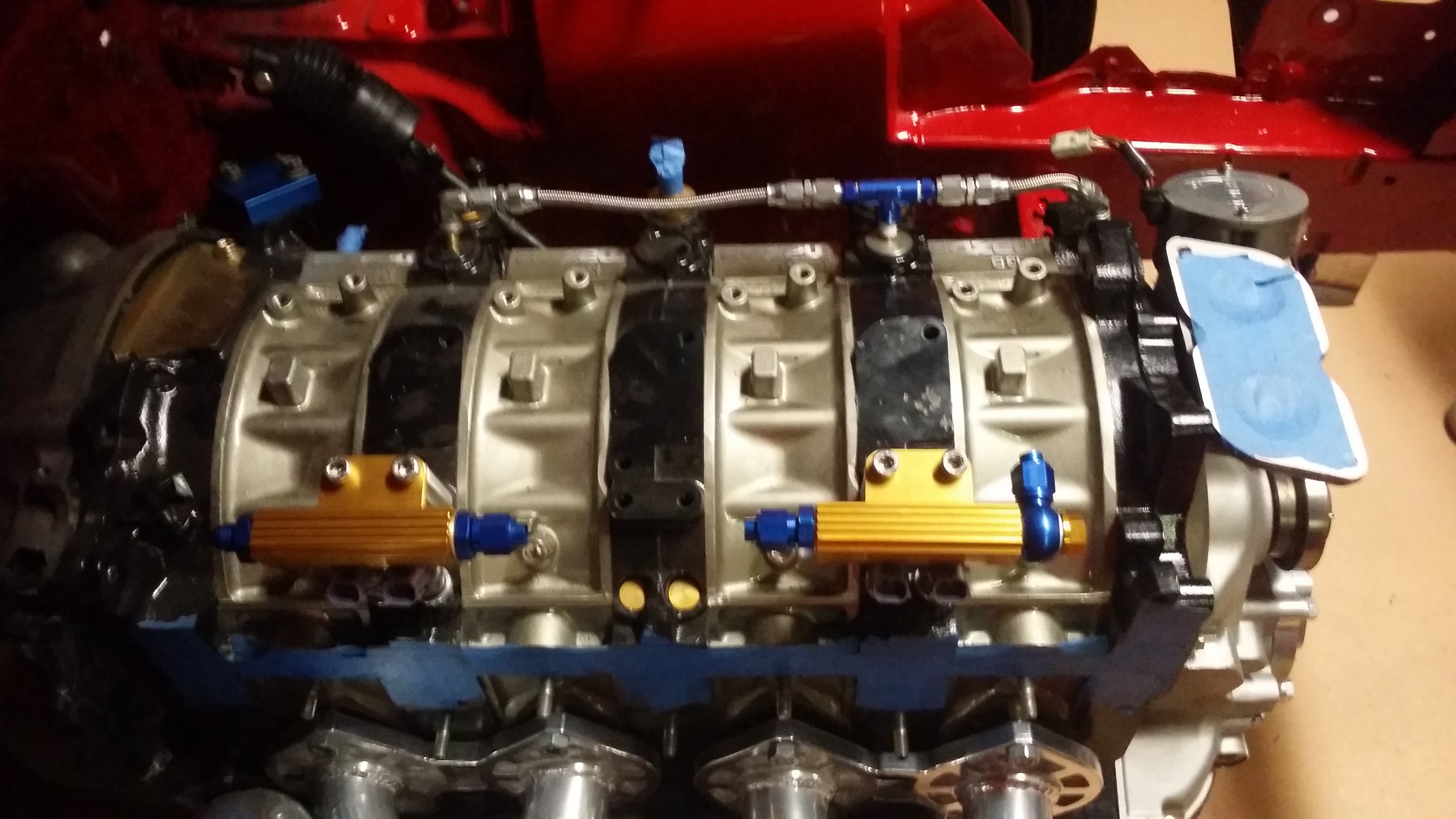

A 26B is essentially two 13B engines stuck together, so we started with two SARD Fuel Rail kits which included fittings, spacers and mounting hardware. The intake manifold has no position for the secondary fuel rail(s), so they were tossed. Since we are not adapting these fuel rails to an existing 13B as they were intended, the adapter fittings were tossed and new ones ordered to allow two primary fuel rails to function as one.

Next I used some aluminum hard line precisely cut and flared to mate the two rails at their exact distance. It was tricky, but I nailed it on the second try. After the center section was installed, the primary feed line was created using the same aluminum tubing.

Finally, the SARD Fuel Pressure Regulator (FPR) location was chosen on the firewall. After two riv-nuts were installed, the FPR was mounted in its new home.

All we needed was a quick fit check of the intake manifold to complete the main engine fuel component installations. The blue and gold offers such a high contrast to the polished aluminum. It really pops quite nicely.

Now we can move on to the heart of the fuel system: The Pumps. There are three fuel pumps required to feed this monstrous 26B.Two pumps are located inside the SARD Fuel Surge Tank which will be installed in the rear hatch section of the cabin area. The third fuel pump is located in the factory fuel tank.

With the fuel tank remaining below the car in it's factory location, a little bit of plumbing needed to be done between the two of them. This is where the black anodized Russel fuel lines and an experienced tube bender, yours truly, came into the mix once the tank mounting location was chosen.

There is something kind of neat about saying that your car has 3 total fuel pumps and two fuel tanks.

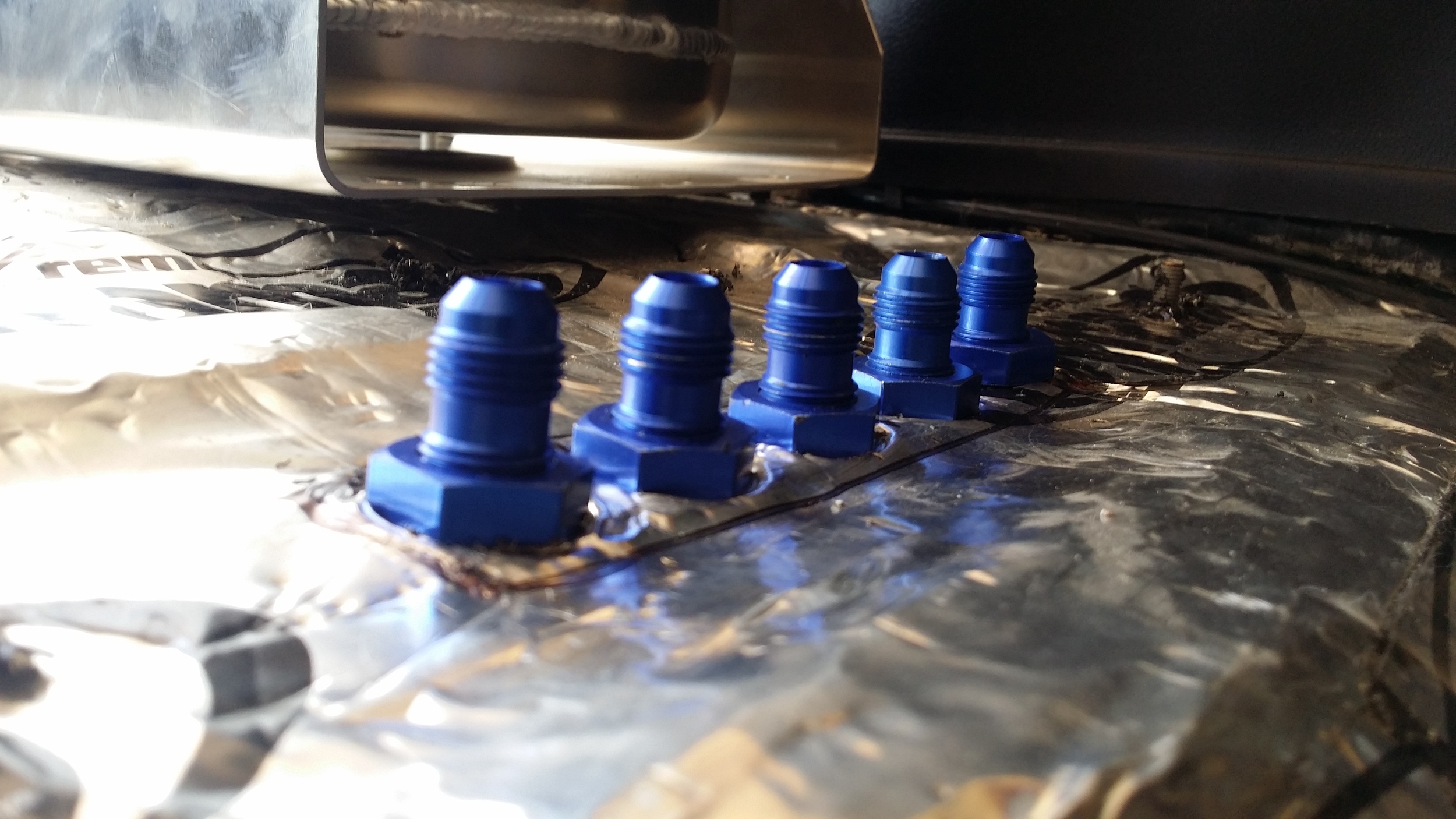

With the front and rear section done, we have to fill in the blanks. The mid section is the easiest but is far from routine. Starting with the bottom side of the surge tank bulkhead fittings, two in and out barbed 90's were added to direct fuel between the two tanks.

Two fuel pumps feeding the engine means two fuel filters. Both Russel filters were mounted under the chassis in an easily accessible location for servicing and maintenance.

Once the locations of the components were set, all that remained was to connect everything with Russel black aluminum hard line and fittings. While it does take a bit of time to seamlessly route everything and connect it, the end result is worth every second. There are no hanging lines or areas to give any kind of problems down the road which is exactly what we want.