Finding the space to mount four coil packs for a 2 rotor engine is no big deal. Aftermarket adaptation of coil packs to a 2 rotor can be even easier. How about 8 coil packs in the same bay? This is going to take some work.

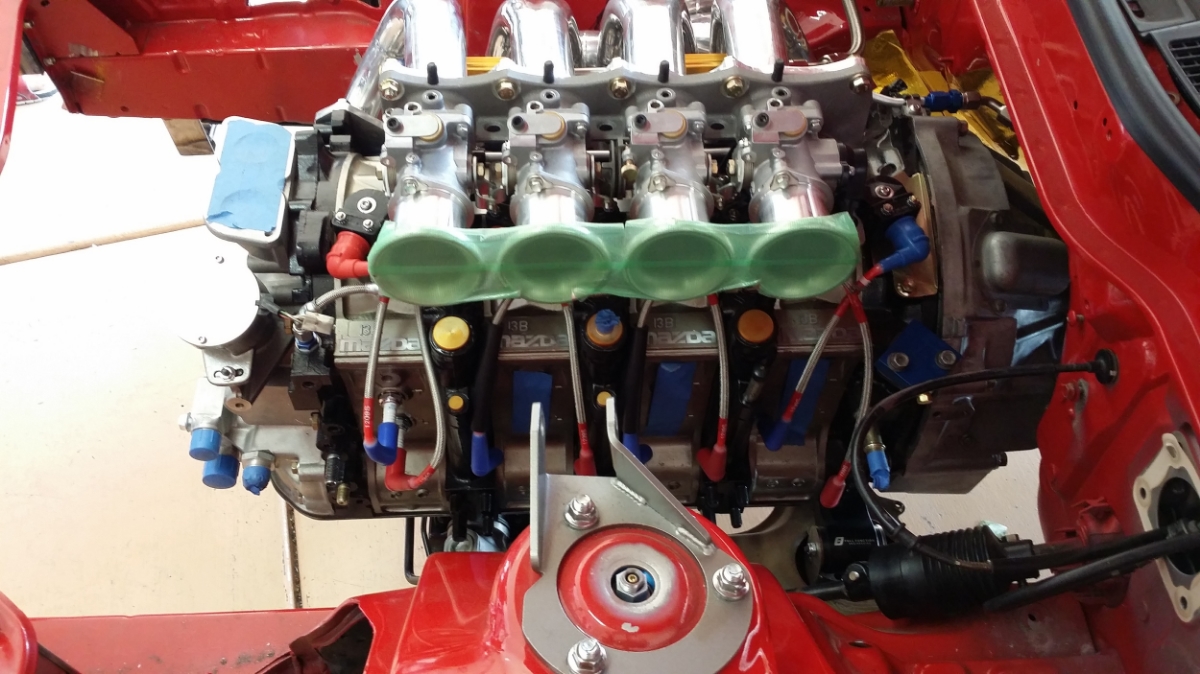

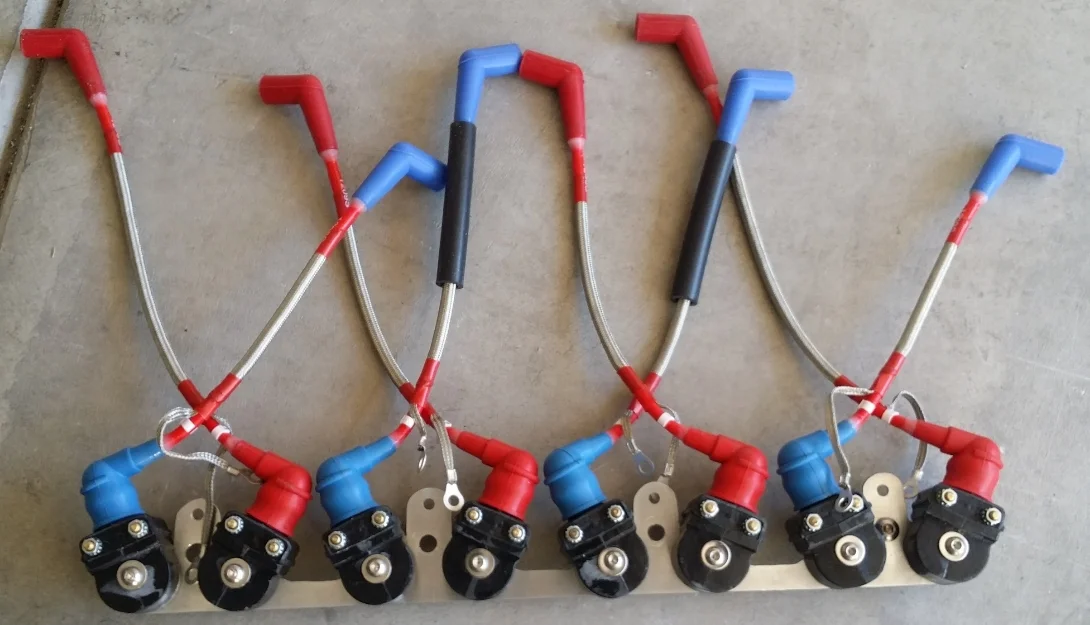

There was quite a bit of discussion leading up to coil pack choice and placement. Since the beginning of the point where I was hired on to this build, the ignition system was still on the drawing board. With time running out to decide, the MoTeC Mercury CDI coils were chosen. This is right where I come in to put all the pieces together.

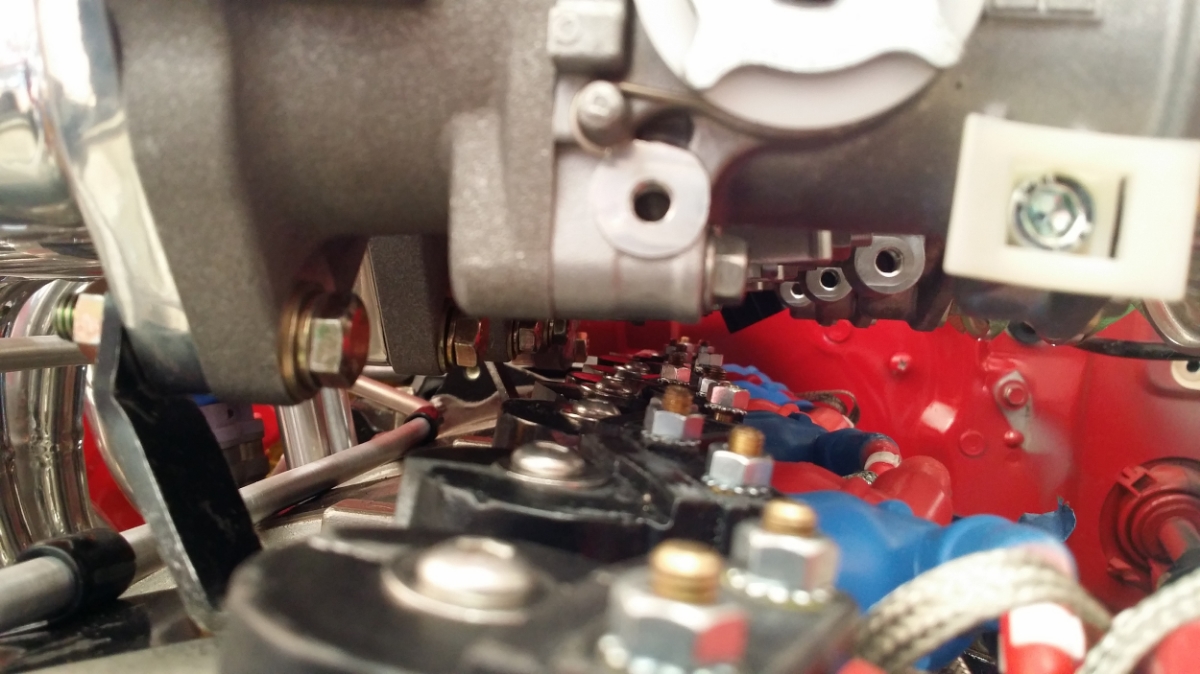

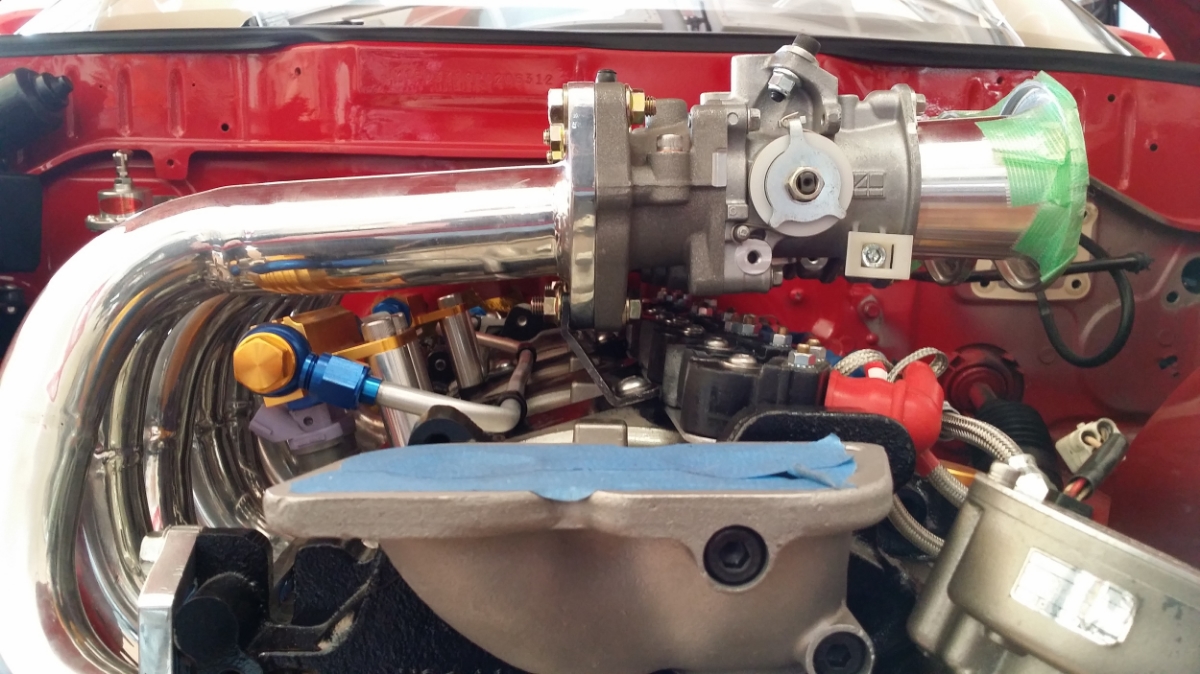

It took only a little bit of time to figure out that we are already running out of space so early in the game. Mounting 8 coil packs in any one location, regardless of their individual size, will demand more than the average mounting space. The only logical solution was to mount the coil packs on top of the engine underneath the throttle bodies. After some measurements and a fit check, I immediately noticed we have a problem. The throttle body above rotor number 4 has a port that hangs low and directly in the path of the coil packs. This was going to be the first thing I needed to modify in order to get the coil packs on top of the engine as designed.

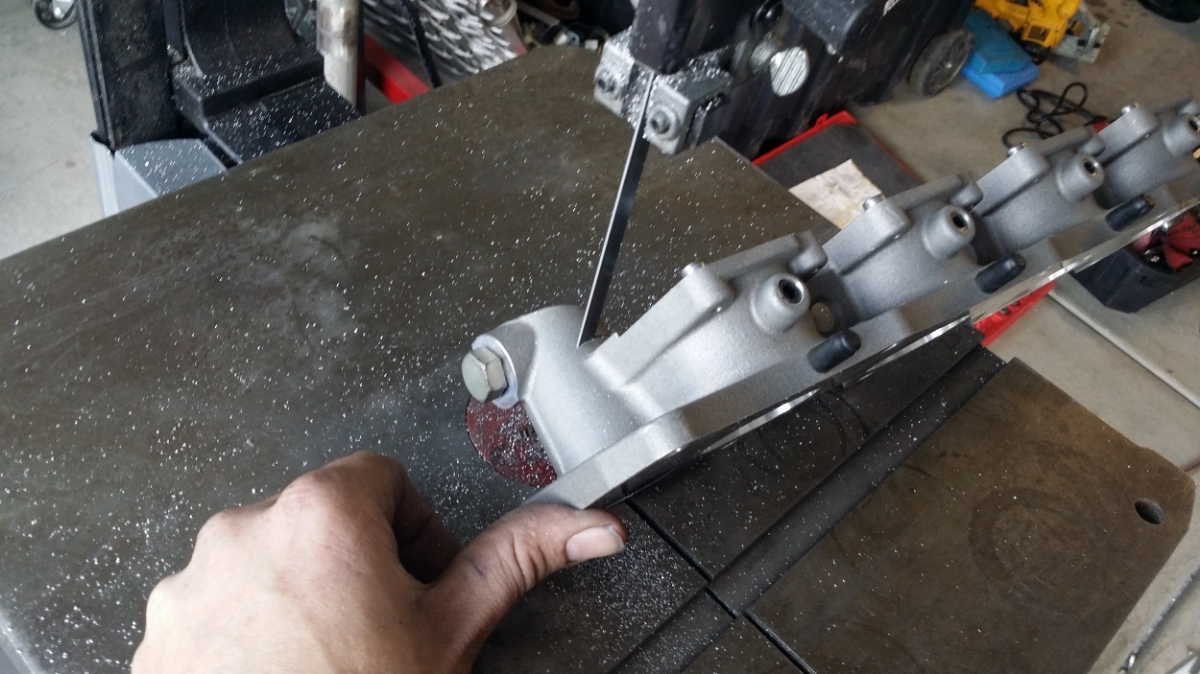

The quickest way take care of this addition was to feed it straight into my band saw. After determining that the casting did not contain any additional voids internally between the small bore and the throttle body bore, I started slicing away at it.

Once the rough cut was made, some smoothing was required to make the lower right edges match the throttle body outline and create more space to work with. Even though this section of the throttle bodies will likely never be seen, I wanted it to look as clean as possible.

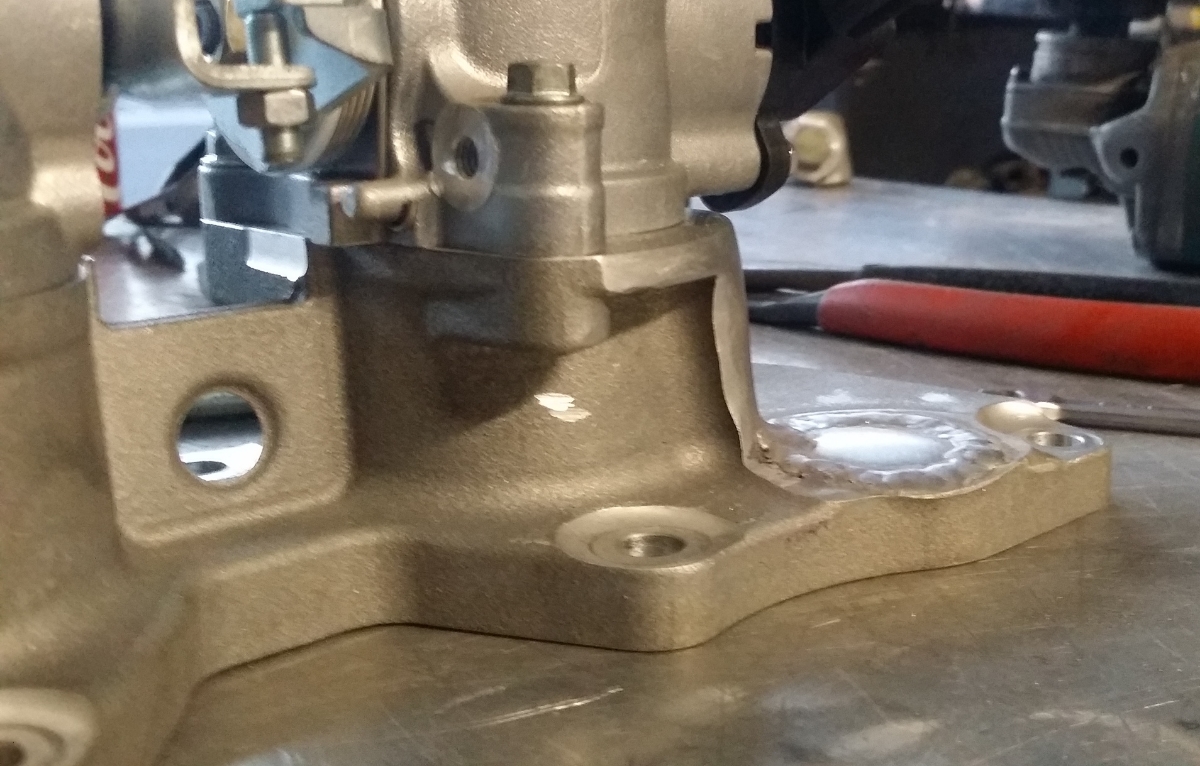

After smoothing and metal prep, a small filler disc was cut and welded in to seal the bore back up again.

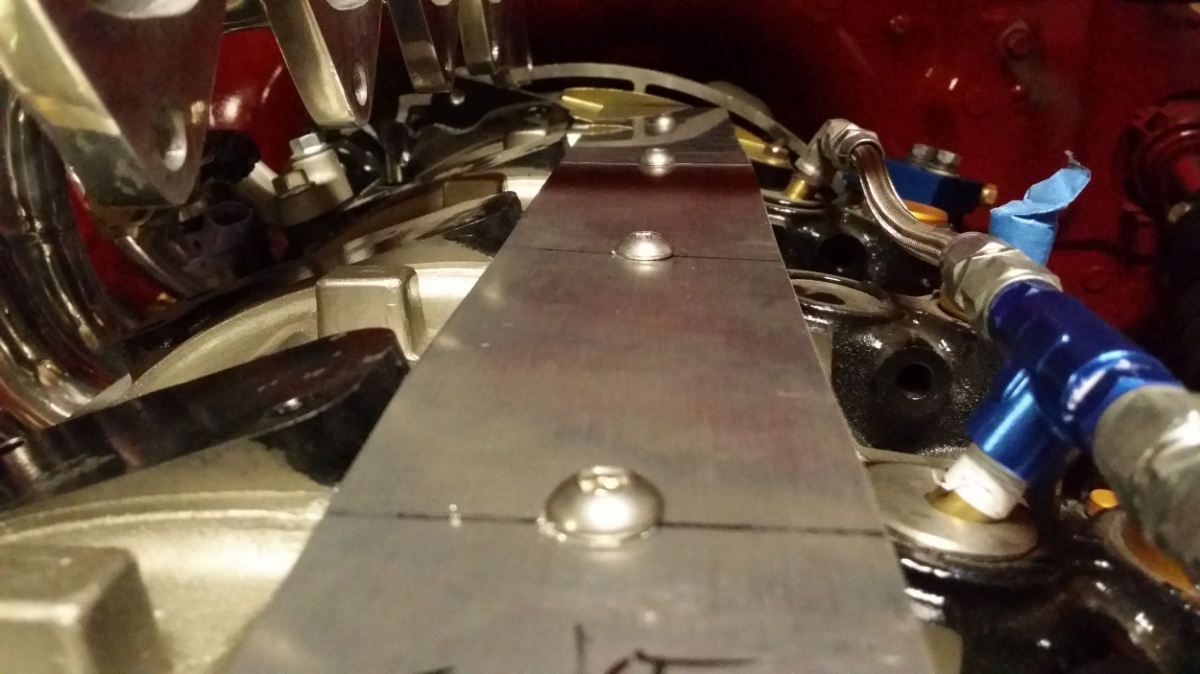

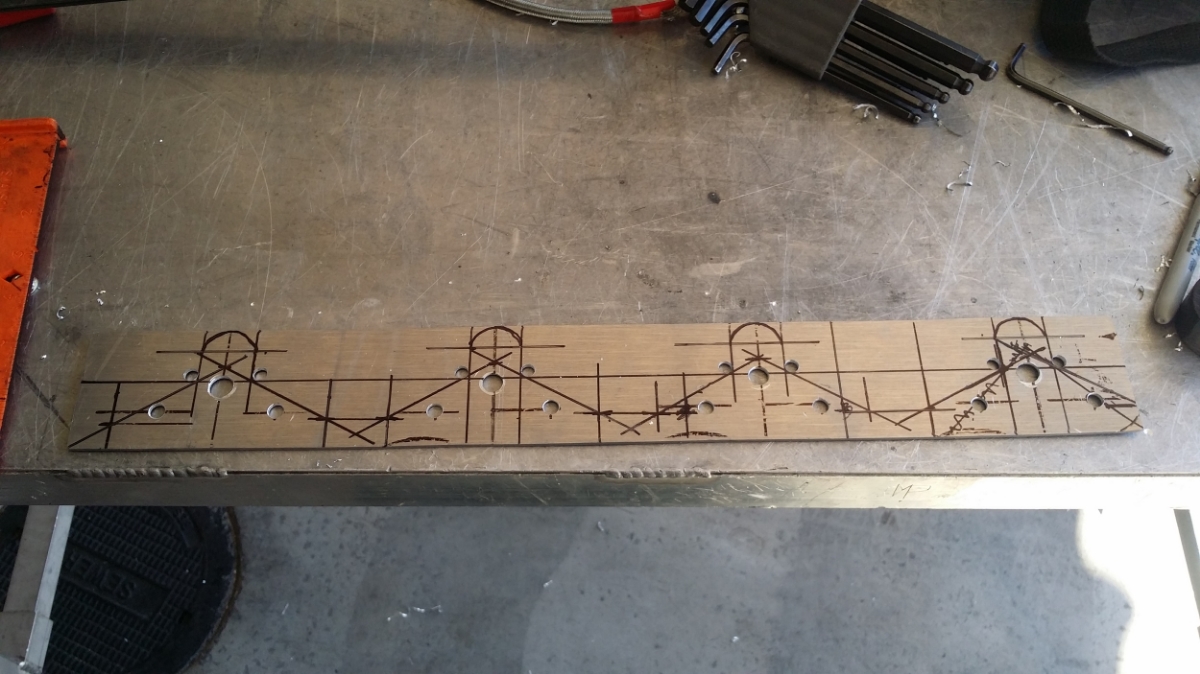

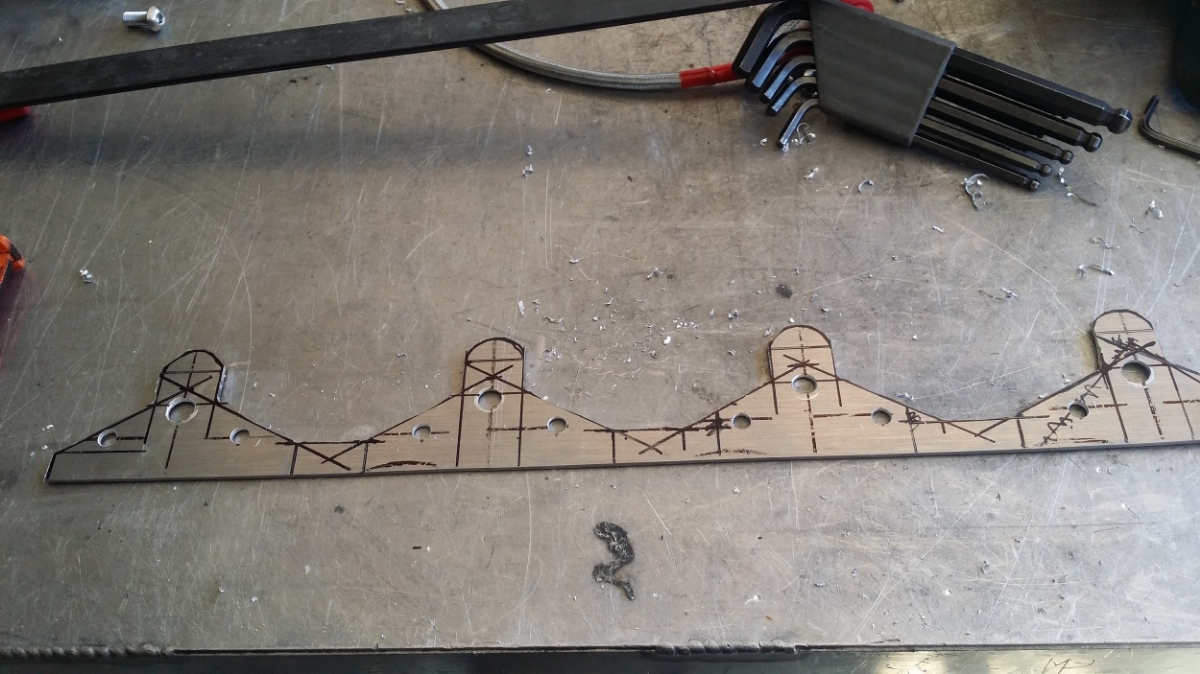

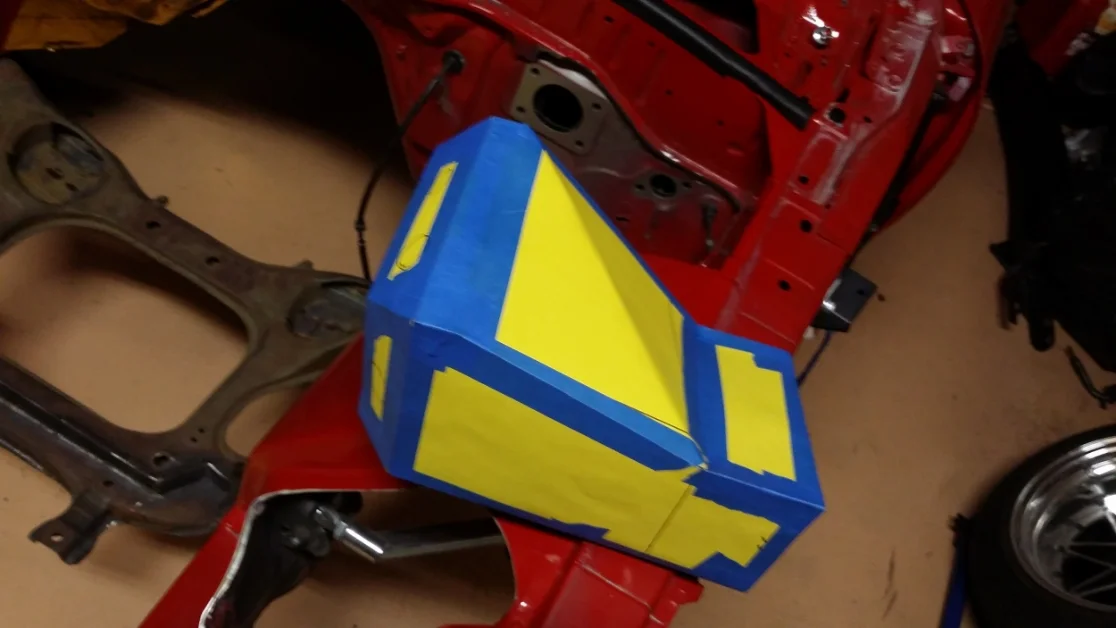

With a clear path, the coil mounting plate can be mocked up and cut. This was pretty simple to do with the band saw and a bit of clean filing afterward.

Next came the installation of the MoTeC Mercury CDI Coils to the coil plate, followed by two brand new Fujita Engineering (FEED) neo silicone noise suppressing wire sets to fire the spark plugs with maximum power. The fun of reassembly can now begin!

Since all 8 coils and wires are on one single plate, servicing them as one removable unit can help save time in the future. The entire unit can be removed as one assembly and each coil can easily be tested or replaced with this type of plate design. It's just one more way engineering steps in to solve the problem.

What do you think about this modification and design? Talk about it in the comments below!

A necessary sub-frame and steering rack modification for 20b and 26B Rotary Engine Swaps in the FD3S Chassis.