Maybe I got a little too carried away in the design of these custom Fender Bars fitted to a Pontiac of all cars, but it sure didn't hurt anything.

I admit it. I really did wonder why anyone would ever want to push the limits of a 2004 Pontiac Grand Am GT. Let's not sugar coat it - there are hundreds of thousands of them driving around every day, in every city, on every highway across the country, and even around the world. I completely support anyone who wants to modify whatever car they own or drive. You simply can't discriminate just because its uncommon.

First and foremost - What is a Fender Bar?

Fender bracing is another common method used to help stabilize and support the front section of the chassis during moments of heavy braking and cornering. The section they service is typically the lower A Pillar section (where the front doors attach) and the longitudinal section that extends forward past the firewall (often call a "fender mount" or "wing support").

Do they actually service the fenders? No.

Where does the term "Fender Bar" come from?

Exactly? It's hard to say who initially coined the term, but the most common answer is likely due to the location of the brace when installed - under the fender.

So, what do Fender Braces actually do?

Take a look at the very simple drawings:

The basic design of your car is illustrated in Figure 1 as it approaches a bump.

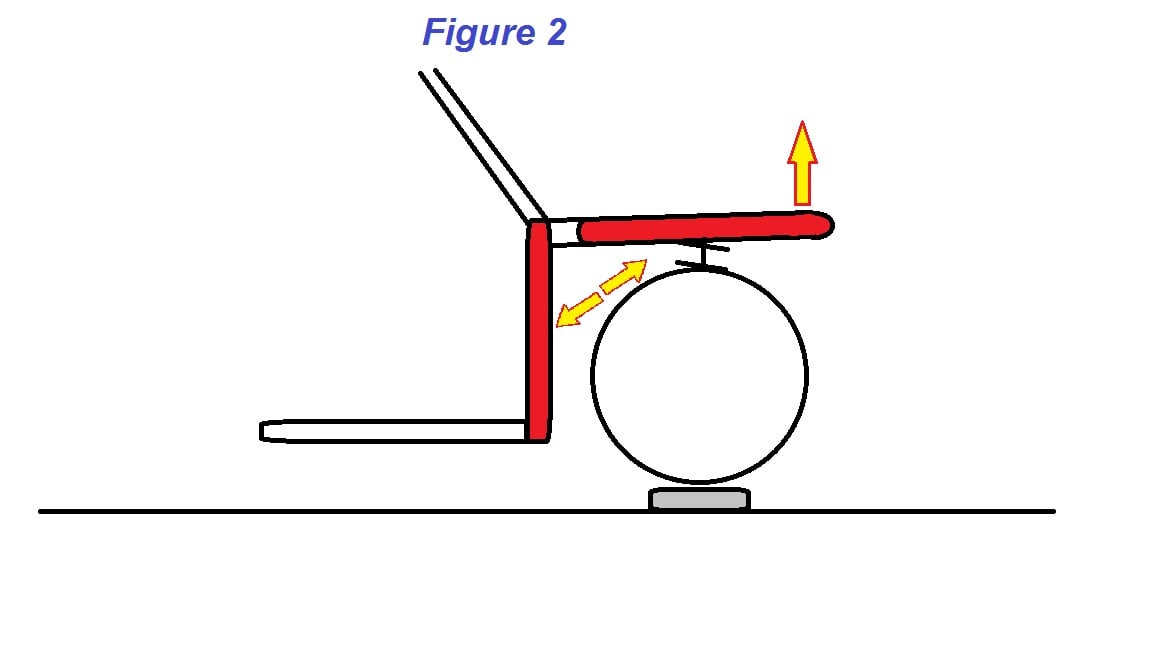

During normal cornering, braking, and even driving over bumps (illustrated), the Fender Mount flexes (Figure 2).

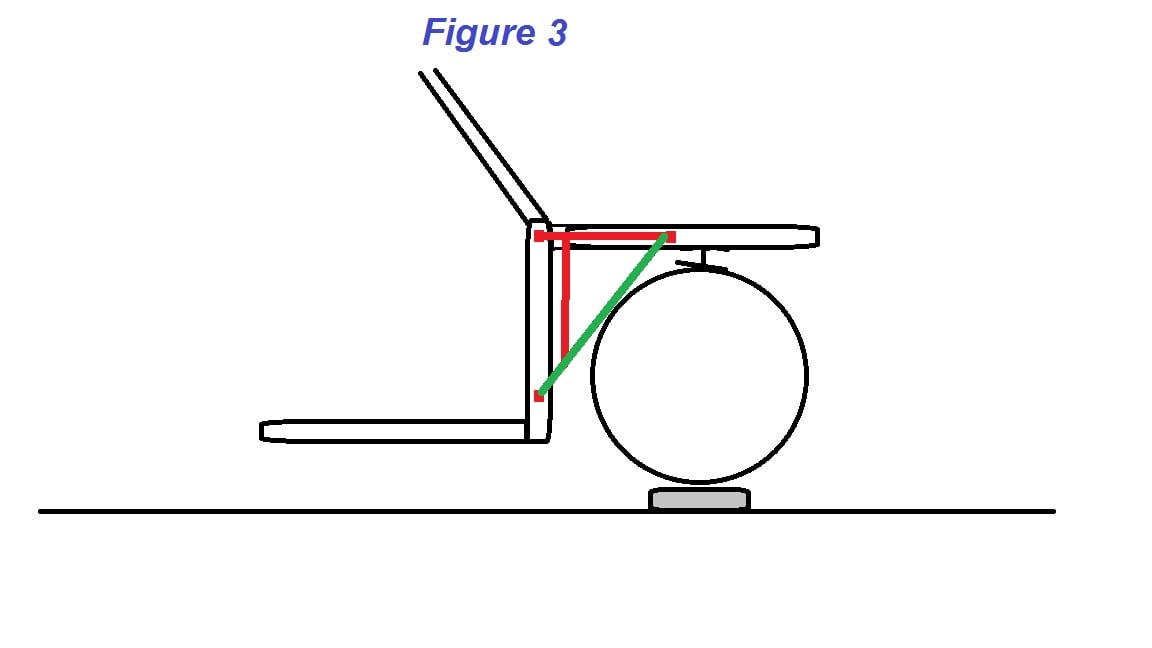

Connecting the lowest point of the lower A Pillar to the foremost point of the Fender Mount will triangulate and brace the two components, thus reducing flex (Figure 3, Green)

Incorporating a single bar or tube will absolutely make a difference, but it will not be maximized. Depending on the installation, the mounting points of the single tube fender bar can become pivot points. While it will reduce flex, it can be further braced by mounting the fender bar to multiple points which braces itself (Figure 3, Red).

Now that we know what a Fender Bar is and the basic function, just how crazy can you get with a set?

That is entirely up to you to determine. The Pontiac Grand Am chassis is rather..... well..... I'll just say it is "husky" and not really meant to go carving through the corners like many other similar classed chassis. It's a family sedan.

Would this Pontiac Grand Am benefit from a set of Fender Bars? Absolutely!

So it was off with the fender to measure and calculate exactly how much space I had to work with. There was so much space to work with that I decided I was going to hold back nothing on this set. The space I had to work with allowed multiple mounting points and multiple planes to build in. I had enough space to essentially get dimensional on my design.

First things first - Identify the mounting points and tie the lower with the forward.

Like many other designs, the door hinge mounting points were used as the upper and lower bracket mounting points. The forward mount was as far as could be managed and accessed for hardware installation.

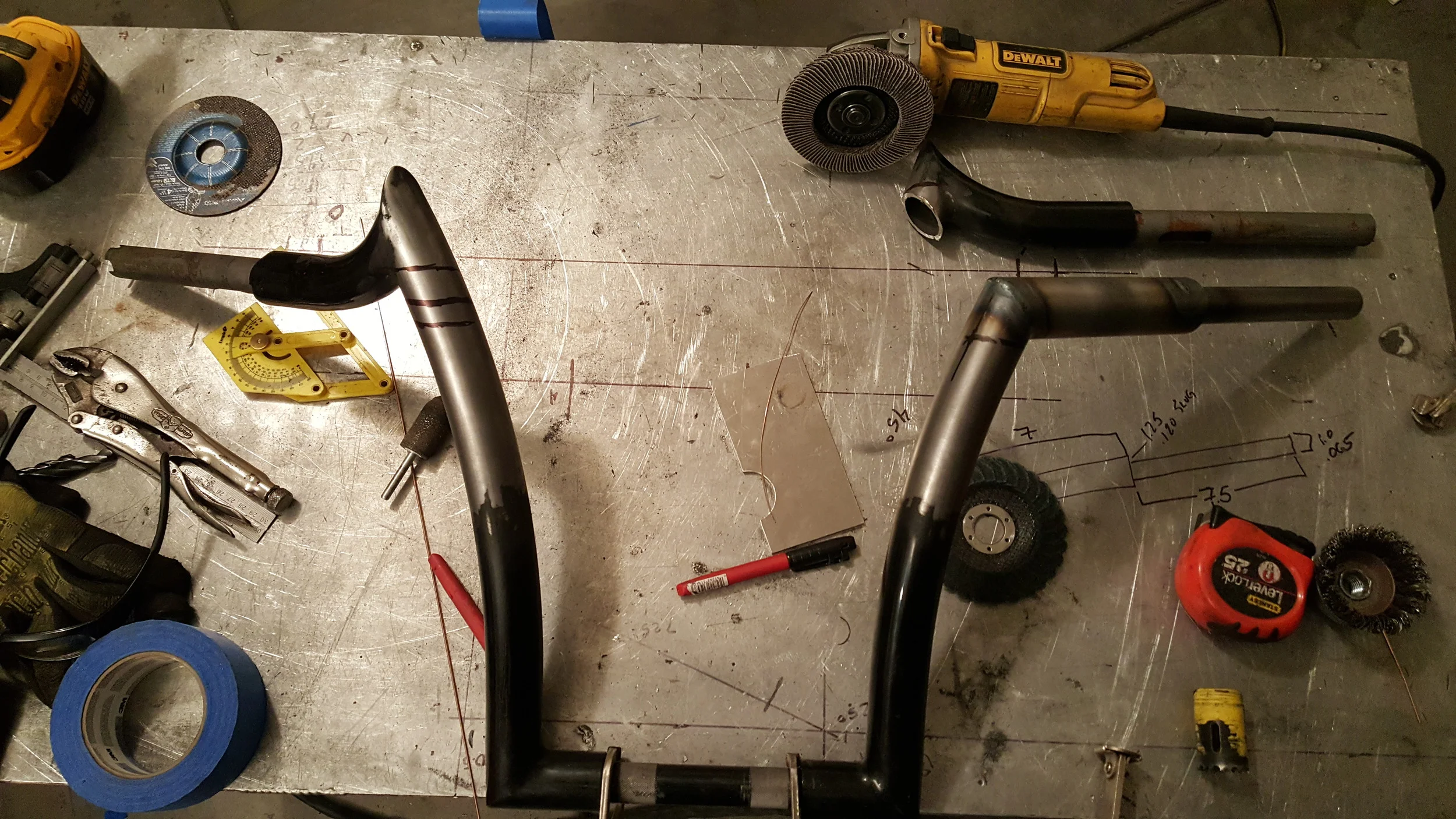

With those 3 points in place, the first tube could be bent and installed. With so much unoccupied space under the fender, the main tube was bent more dimensional to bring the design outward.

As stated earlier, the Grand Am chassis is rather husky and much bulkier than the average family sedan. There was a massive gap from the wiper cowl opening that had to be cleared in order to reach the forward mount. Bending a single tube to reach would be sufficient, but there would still be a high amount of flex in even the fender bar itself since it is so huge. Adding a fourth mounting point would further reduce the flex in this design.

With the upper tubes now in place, the rear tubes were added to complete the basic design. Careful consideration must be given when designing and placing the rear tube(s). When the door opens, the sheet metal of the door skin will often swing into the fender well area. It is important to ensure your rear tubes will not contact the door when it opens.

Since the design of this set is dimensional, some additional bracing was added to tie it all together.

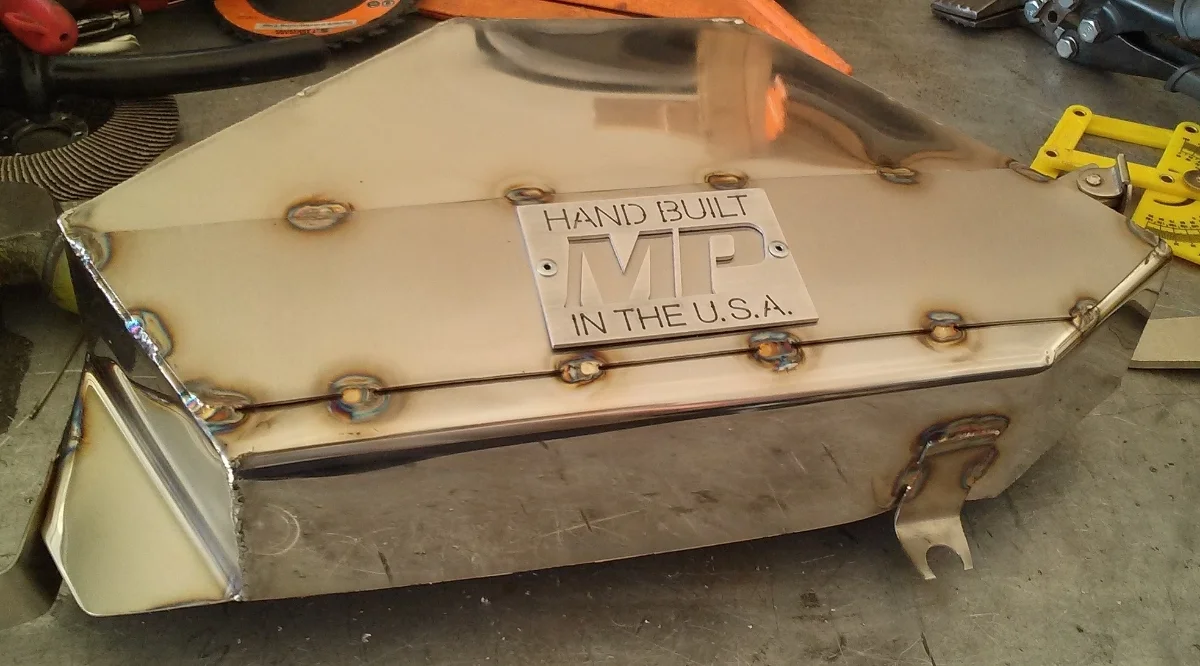

After a good blasting of the metal and a final coat to match the car, the final installation revealed one of the Craziest Fender Bar sets ever created!

Overboard on the design? Perhaps.

Worth every bit of it when you take the first corner? You bet!

I have never really "driven" a Pontiac Grand Am in the sense trying I was trying to push the limits in a very spirited fashion. I mean, who does? It's a Pontiac Grand Am!?!? Well, I was extremely impressed when I went into the test corner and found the back end getting loose while the front stayed nailed to the ground. It was as if the front end of the car was on rails. Every reaction to braking was positive. Every bump in the road was no longer accompanied by a nasty floppy shutter of the chassis. EVERY corner was solid!

The verdict is still out on whether or not Fender Braces actually do something or not. Structurally speaking, they do serve a purpose. From the "every vehicle" standpoint, the answer is really dependent on the chassis design, the design of the Fender Bars themselves, and you - the driver.

Above all, I learned couple very important lessons from this build. Never underestimate the will power of a vehicle owner, and never underestimate the potential of a car. If it can be done, it will be, and nobody should stop you from doing it.

Edit: 14-Jan-2016

I had a really great question come in regarding installation in relation to the chassis itself.

"Should you have the chassis resting on the ground, or lifted in the air when installing the fender braces?"

This is a fantastic question which has a couple of answers and viewpoints I can address. The basic installation for primary function of the Fender Bars is while the chassis is on the ground.

While the chassis is on the ground at rest, it is technically flexed, but it is at a normalized position. The idea is to brace it as is so that when it flexes, the bracing will reduce the flexing in either direction while the vehicle moves. This will help maintain the normalized position..

If you pre-load the braces, you will ultimately increase rigidity in one direction, but dramatically reduce it in the other. So if the Fender mount is sloping down during install, then braced and placed back on the ground, the chassis will have less flex upward under load, but will spring downward on the rebound which will decrease stability.

This also leads to another interesting possibility. You can absolutely calculate and engineer your fender braces to function under a pre-loaded condition or position. There are dozens of reasons and uses for doing so, but they are basically dedicated installations.

An example is a track car that spends more time going left instead of right on a course. The builder can utilize some of the pre-load on the right front corner which may offer better stability. While this is not necessarily practical for a full chassis car designed and built specifically for a particular form of racing, it may suit a modified car intended for a particular style of racing.

Purge Blocks actually serve more than one purpose. Do you know what they do?