What career did you dream of when you were little? Was it becoming an Astronaut? How about Lawyer or Doctor? Did you dream of being a super hero?

Many of us went through the phases of common potential career choices in our youth. I can only speculate that most of my friends were choosing the career paths that involved large sums of financial awesomeness. As a child, I never really knew specifically what I wanted. I knew I wanted to help people and make cool stuff. It wasn't until my teen years that I discovered cars and metal and figured out fabrication and engineering was right where I should be.

Queue Zach (AKA "Grizz") and his Mitsubishi Mirage LS Coupe'. When you are immersed in racing as a child, but dealt with a strict upbringing to always practice and maintain responsibility, you will likely shift your inner dream of being a race car driver to something just a bit more directed at life.

After 8 years of seemingly empty retail management work to fulfill a near empty feeling, Grizz finally decided that the spirit of racing can not be shut down, and he can no longer ignore it. It's never too late to start.

Like many people wishing to get into the industry, Grizz knew he had a lot of work ahead of him. Like many others, he started researching cars, parts, racing, and anything else he could get some information about. As time went by, Grizz found that the true spirit of his inner racer was best defined by becoming the master of control in the Rally world.

While it is a fantastic sanction or racing style to shoot for, Grizz knew he has virtually no experience, so immediately jumping into a rally car would probably be exhausting to his budget. Let's face it, one would probably spend more money on mistakes than taking the time to learn how to avoid them. This mentality is what directed Grizz to the starting line of his future; AutoX.

Choosing the vehicle for the job can be challenging to many of us. Hours of research, millions of opinions, good support vs. generic mods, and even the community surrounding the car can all play a role in your decision process. Grizz had a pretty easy decision when it came to picking a car after a relative decided that a few hundred dollars would satisfy the sale of one Mitsubishi Mirage.

Wait.... what? A Mirage? What's a Mirage?

After countless hours of research, Grizz found a small community of enthusiasts where he discovered some of the craziest Mirages out there along with the uncommonly known heritage as the "stripped down early model Evo" here in the states. Now Grizz was on to something...

With the guidance of a few friends, and some solid direction from a couple local Mirage enthusiasts, Grizz now had the knowledge to put this build and dream into gear. There was only one small problem: experience.

As is with many other enthusiasts, you will eventually learn about how far your skills will stretch when it comes to something you have no experience with. You may also come to a point where you realize that the standard "off the shelf" bolt-on part often performs better in the sales description than attached to your car. Grizz knew that his future would be dependent on something more than just another bolt-on.

Good fabricators are the ones who go above and beyond the cutting, welding, and assembly of parts. Good fabricators are the ones who create a specific function or solution for a specific use. This could be as simple as a singular brace to reduce flex, or as complicated as a complete tear down and reconstruction of a chassis to eliminate variables. Either way you slice it, you will often find that bolting-on the same part as your opponent will only net the same results. This is why good fabricators play a crucial role in the build process when taking a car from the level of enthusiast to a level of very serious.

We begin the mod list with a budget. Once Grizz concluded his research and set a realistic budget for the beginning mods, we laid out a basic "Power and Performance" package which would net some great results on the track.

Depending on the type or sanction of racing, managing handling aspects of the vehicle is far more important than making it go faster. It is for this reason that more emphasis was placed on stiffening up the chassis with a custom tailored set of braces than the actual performance of the engine itself. However, there must be a delicate balance to the performance aspect which is power.

Increasing the power output of a small engine (especially small Japanese engines) is very simple. All you really have to do is get more air in and out. The best way to solve this for this particular build was to add a custom cold air intake, a larger throttle body, and a custom built exhaust system.

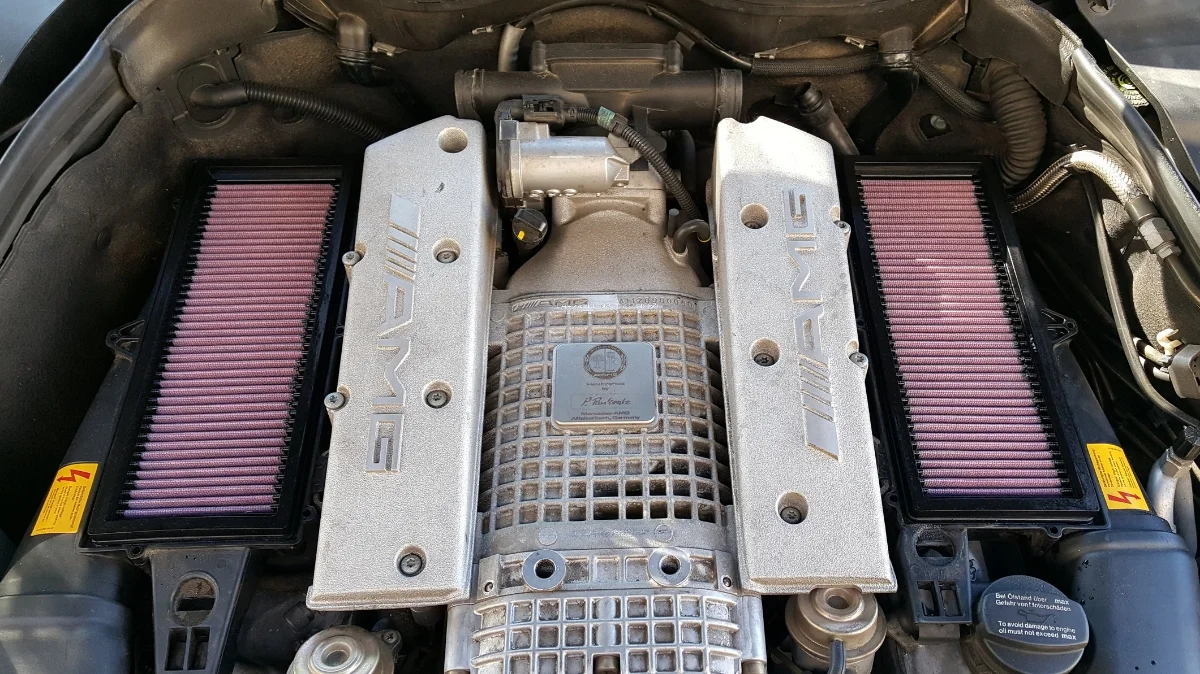

The good engineers at Mitsubishi made some of the easiest mods possible by sticking to common patterns. What this means in the production world is a minimal amount of changes needed to be made to facilitate the manufacturing of different parts. What this means in the modification word is so many parts from other model Mitsubishi engines and chassis are easily interchanged without significant modification.

Intake

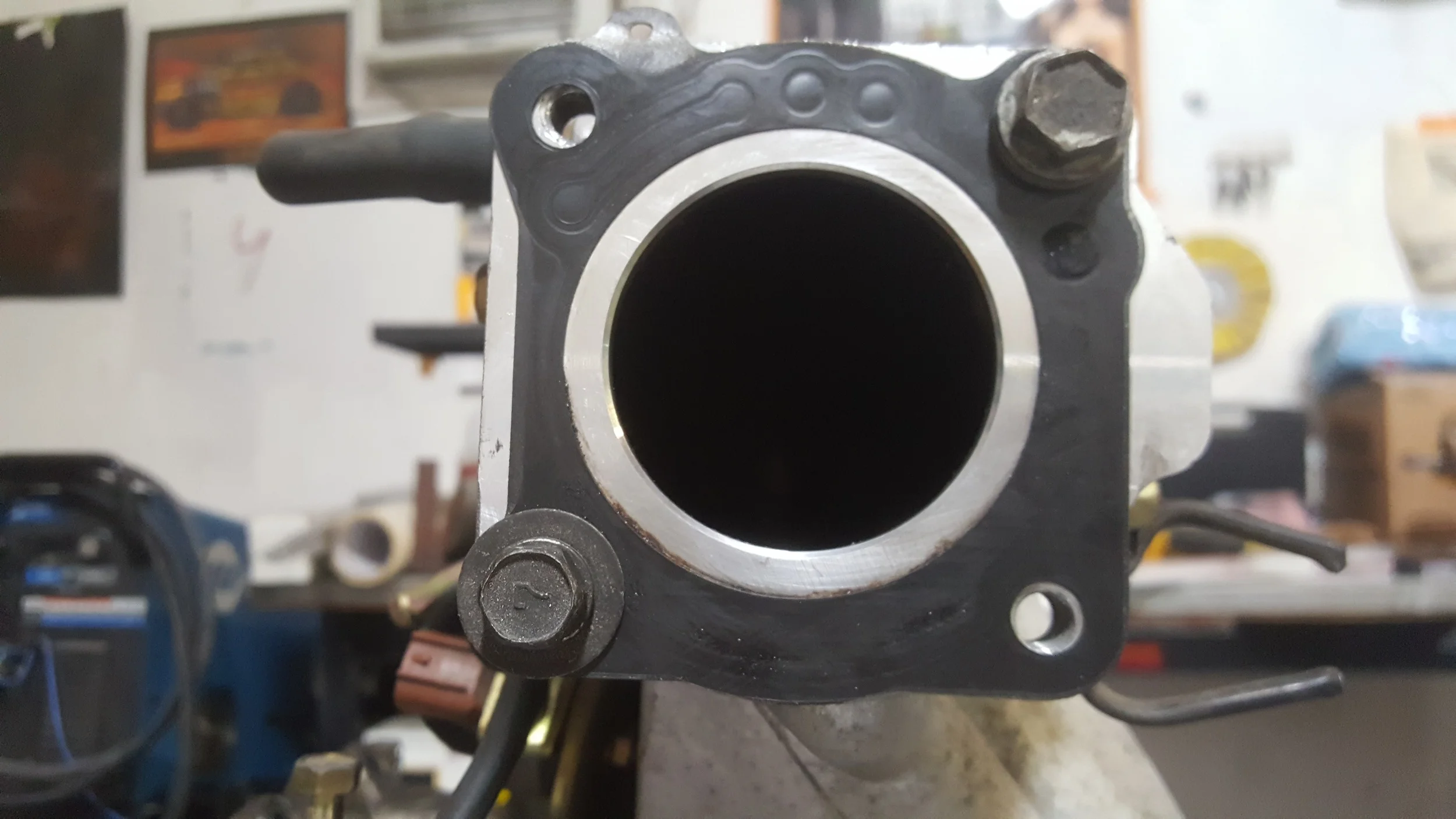

60mm (left) vs. 52mm (right)

The Mitsubishi 3000GT featured a 3.0L V6 that was fitted with a 60mm throttle body. As it turns out, that particular throttle body maintains the exact same bolt pattern and sensors as the smaller 52mm Mirage throttle body. Since the Mirage throttle body maintains a smaller diameter, the intake manifold needed to be ported to match the new larger 60mm bore of the 3000GT. This was done simply by laying the gasket over top of the Mirage manifold to mark out the bore of the 60mm. Then came the porting.

After a very thorough cleaning and mild de-greasing of all passages, the intake manifold was fit back on to the car along with the new 60mm throtte body.

With larger air induction capabilities in place, the factory intake system simply will not suffice. If a chain is only as strong as it's weakest link, an engine can only breathe through its smallest port. Following that simple logic, note that the throttle body is right on the middle of the intake system of the engine. If the middle of the system was increased, the beginning of it needs to increase as well.

To increase power potential of the 60mm throttle body addition, a custom cold air intake was built to maximize potential air flow and lower the intake air temperature.

Grizz made his intentions to run the car on the street between competition very clear, and while it doesn't rain here in the desert very often, there is no reason to risk something that can easily be solved. The routing of this intake, as well as the use of specific couplers, will allow Grizz to place the air filter inside the engine bay by removing the coupler to the lower tube, and installing the air filter straight to the MAF sensor. This will eliminate the potential of water damage to the engine if he is ever caught in a storm.

Exhaust

Now that the air can easily go in, we need it to easily get out. The previous owner already had some mild exhaust work done which featured a long tube header and a 2.5" crush bent aluminized exhaust. Along with the larger exhaust tube, an appropriately matched 2.5 inch catalytic converter was added.

There are only two potential issues with the exhaust system that was in place.

First was the header. Long tube header systems are really more suited for the top end of the power band. While this is great for most types of racing, it is not very well suited for the up and down RPM range of autocross. A completely different system needed to be implemented in order to maximize the power band over a greater range.

The other potential issue was the muffler. Most people want a better performing exhaust system without the better performing noise associated with it. The previous owner set out to solve this by having a factory sized muffler installed to the rear. Even though the factory size muffler was fitted to the 2.5 inch exhaust, it only flowed with 1.875 inch potential.

While one could argue the potential flow differences between crush bent and mandrel bent tubing, it is not a significant enough difference for the current power demands as of yet. The crush bent tubing will not reduce the flow potential enough to require a full mandrel bent system.

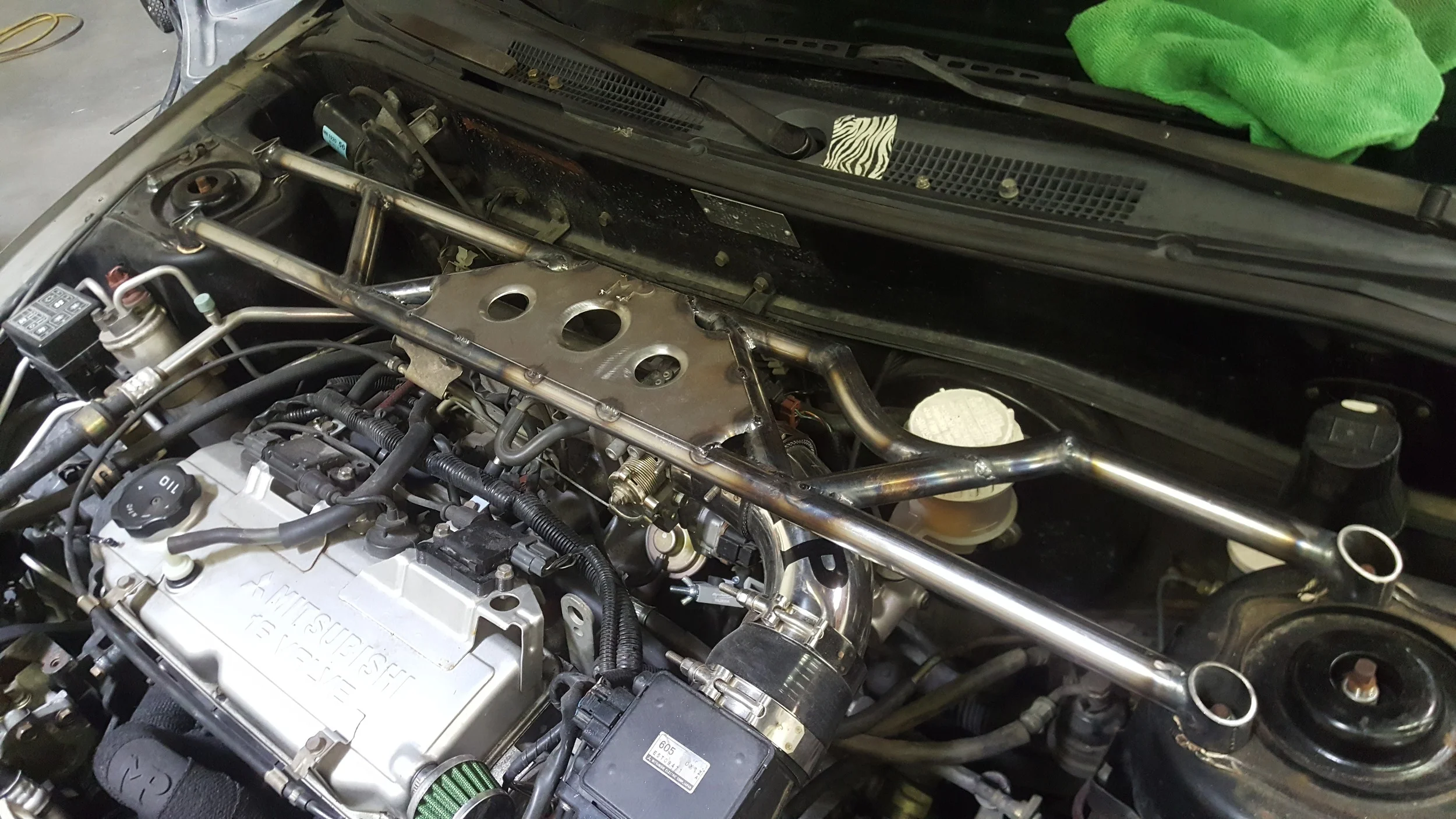

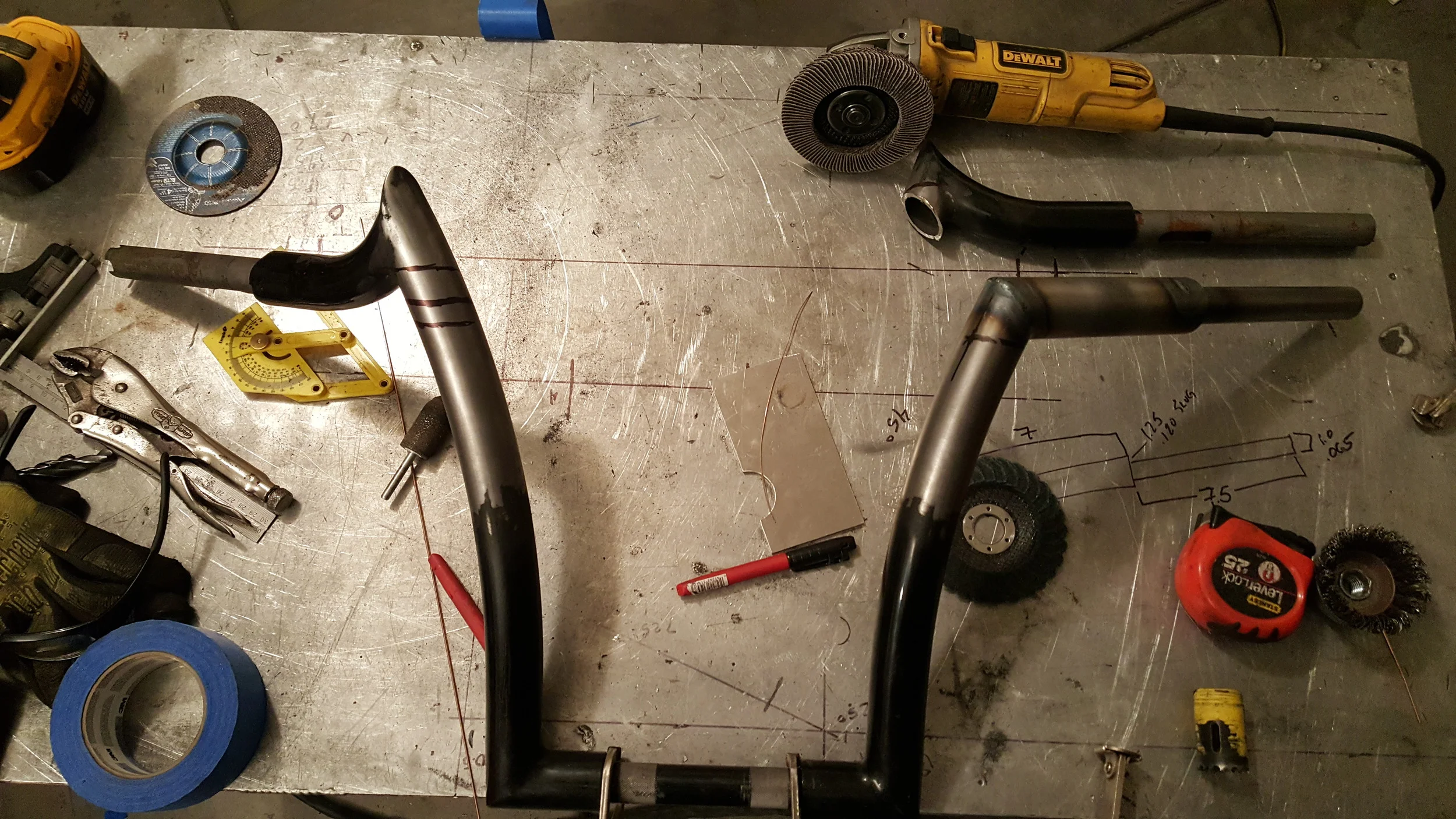

To solve the header issue, a custom built "shorty" style with a high flowing polished stainless steel downpipe was built to take the place of the long tube. This particular header was built with the proprietary flow design which is exclusive to Merrill Performance. The shorter 4-1 design, combined with our technology allows the header to flow and perform over a much larger power range. The addition of a stainless downpipe means it will be able to take the abuse of racing without failure.

Different engines make different sounds. Different components such as headers, catalytic converters, resonators, and mufflers will manipulate those sounds. Different metals used to construct an exhaust system will further tone those sounds as well. Choosing a muffler can be a very daunting task as the muffler alone will not be the only factor in the exhaust note. One example is using the same muffler on the same system of the same car, but one uses stainless steel instead of aluminized steel tubing. The exhaust note will make two different tones.

Most people take to forums and popular places like YouTube when conducting research on exhaust systems for their car. While there are thousands of videos out there, they can still be misleading since all of the factors are not commonly listed, and the quality of the audio vastly varies based on what was used to capture the sound.When it came to chossing a muffler for Grizz, experience was the only way to get extremely close to the results he was after. With a bit of discussion regarding tones and volume, it was decided that a simple 2 chamber muffler would net a smooth tone without sending a sound signal from over 10 miles away.

To further enhance the install, the muffler was kept tucked away with only a stainless steel tube for a nice clean reveal.

Chassis

With a solid start to power potential increased, we can get to work on making this car handle. While most compact import cars handle better than most muscle cars in stock form due to their compact design, they still lack in other areas. Some speculate that it is due to the design of the compact car being made lighter by reducing the amount of support bracing, while others say it is because they were simply built to get groceries instead of take corners. Either way, a solution needs to be implemented.

We have learned about the importance of supplemental bracing such as Strut Tower Braces from the Video Build Blog here, and the function of Fender Braces in this Build Blog here. Adding a custom tailored solution to this particular chassis will absolutely help increase the handling, braking, and stability that AutoX racing demands.

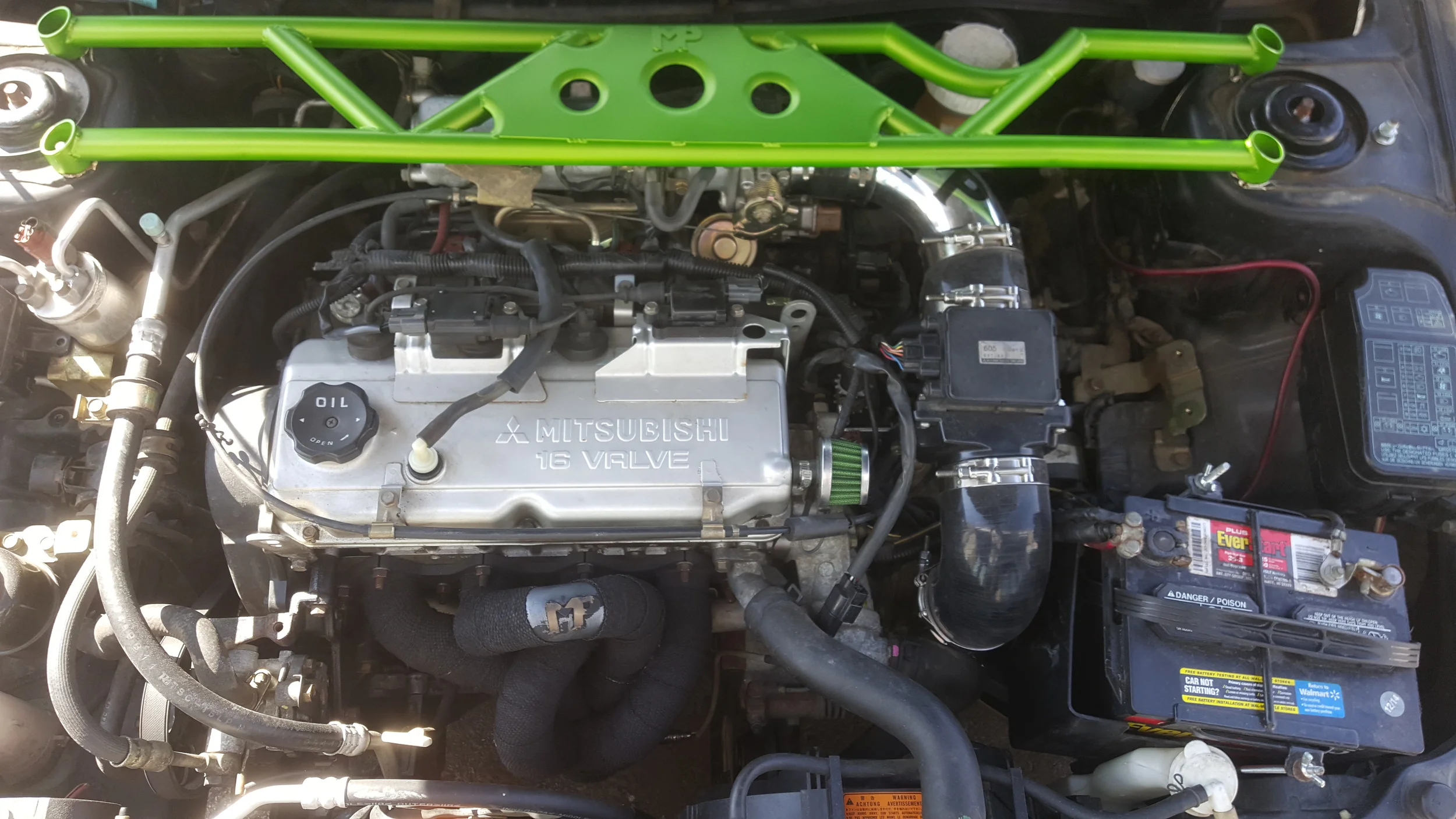

A front strut tower brace, rear strut tower brace, and a set of fender bars were fabricated and installed to meet those demands.

As is with almost all custom orders at Merrill Performance, Grizz had the choice of any color he wanted for his chassis braces which was a magnificent green pearl that shifts its tone and depth in certain lighting.

While this Power & Performance Package is just a start, the options for future mods are near endless. Eventually there will be more mods to suspension, fueling, ignition, and quite possibly some internal engine mods to really bring the potential of this car up.

As updates with Grizz and his racing career happen, I will continue the updates and future mods!

You can also follow along with his progress on Instagram @Grizz_the_Driver

Injuries are inevitable. Get used to it or find another profession.

-The Old Heads