Engineering a harness bar is relatively simple as long as you know and understand the ins and outs. Building it is the other half of the battle. Here's how to do both!

Let's start this off with the vehicle: 2013 Scion FRS 10 Series.

While this is one nice ride, it can be a little bit slim on the bolt-on parts availability. There are a few specialty pieces, as well as a few generic harness bars out there, but at the end of the day, do you really want to run the same thing someone else has or have a component you depend on fail because it is just another "universal" design?

The moment you say "No" is the very moment you either call a pro, or pick up the tools.

Engineering a harness bar is relatively simple as long as you know and understand the ins and outs. Building it is the other half of the battle. While this video is specific to the Scion FRS, the theory applies to all designs similar to the one built in the video.

First you need to start out with a mounting solution. This was accomplished by measuring the correct angles and bending some 1/8" flat stock. As demonstrated, a standoff was required to allow enough swing room for harness bar adjustment. The brackets were also bent in such a way that they installed within the factory opening in the trim plastic where the factory seat belt was located.

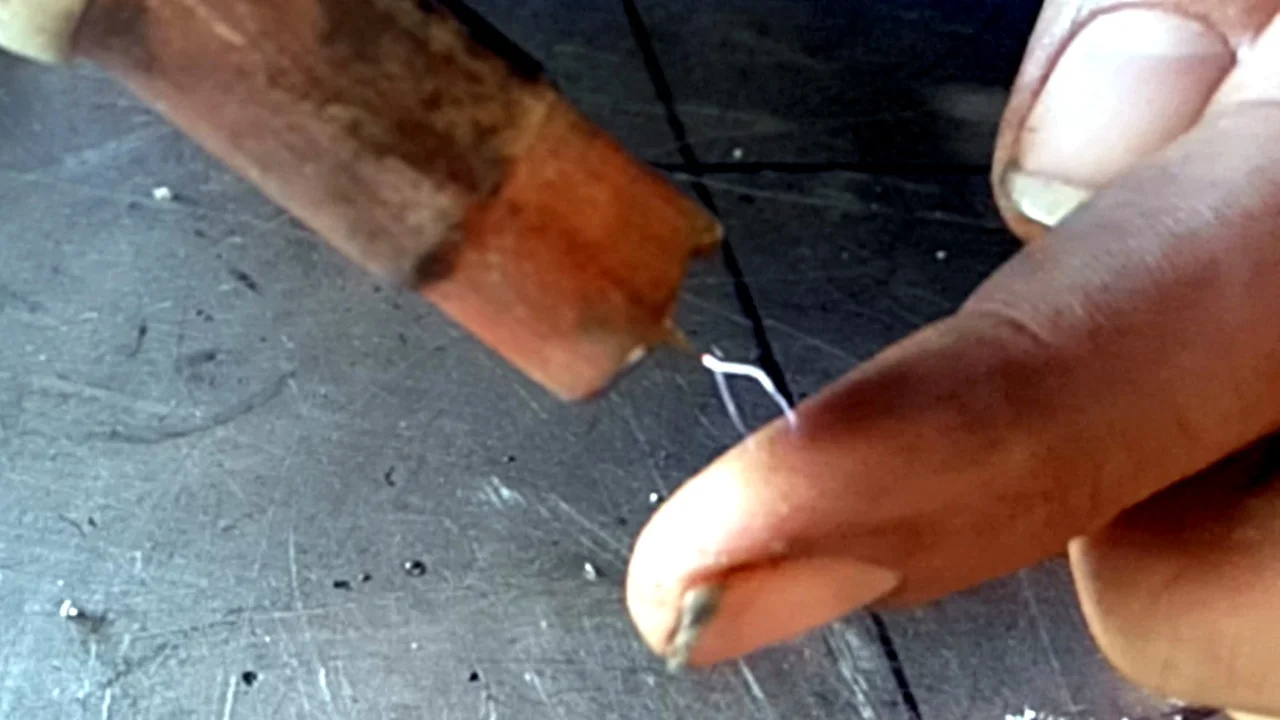

Once the harness bar tube was bent, it was discovered that the location of the bolt hole beneath the plastics hindered the ability to install the harness bar with the plastics on. In other words, there was no way to access the bracket bolts (to the chassis) with the B Pillar plastic trim attached, and there was no way to install the plastic trim after installing the harness bar. A mounting solution needed to be devised in order to mount the harness bar without cutting away at the plastics. The solution was a large bolt to fasten the bracket to the tube. The bolt screws into a nut welded to a disc, which was welded to the harness bar tube.

As explained in the video, the position of the support legs is very important. In addition to the support legs, the angle and placement of the harness bar is important to load disbursement. Support legs mounted to the outsides of the harness bar will cause the load to bend the tube forward at the the center causing a failure.

Some attributions to harness bar failure include:

- Incorrect tubing (diameter, wall, material)

- Incorrect placement (angle, height)

- Incorrect support placement (too far outward, or not enough support tubes)

- Inferior hardware or brackets

- Installation error

While these are only a few attributions, they are usually the top reasons for harness bar failure. Understanding the load and placement of supports on a harness bar system may save a person from serious injury or worse.

The bar less likely to bend is the bar with the least amount of space to bend in. As such, two support legs perpendicular to the harness bar, as evenly spaced as possible to allow no less than shoulder width, and no more than seat width, will be evenly supported. The space between the outer mounts and each support leg will be less likely to bend with the load if installed correctly.

Lower support brackets should be fabricated from the same material as the brackets for the harness bar tube. In this case, the same 1/8" steel flat stock was used with an 1/8" mounting tab. Rather than adding an additional hole to the chassis, the seat mounting hole was used as the lower bracket mounting location.

Once the harness bar ad brackets came back from coating, all there was left to do was marvel at how awesome a custom built harness looks when it is color matched to the rest of your Silver 10 Series Scion FRS.

Help fund future episodes of The Fabricator Series with your Donation and receive exclusive SnapChat access! Even the smallest donations go a long way.

Do you have any questions about either video?

Do you have something to add?

Drop your comments below and join the discussion! I'll be happy to answer what I can!

Purge Blocks actually serve more than one purpose. Do you know what they do?